|

|

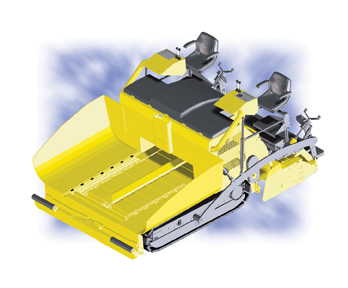

BOMAG BF6615 Commercial Paver

Weighing in at 9300 kg, the BF6615 features a 99-hp Cummins water-cooled turbodiesel engine. The engine’s ECO-mode feature saves fuel and reduces noise by automatically lowering rpm’s during stops and pauses. At the same time, an exclusive load-sensing hydraulic system lowers fuel costs by delivering power only when needed. The new design, UNIMAT 2 full-width floating screed has a standard 2,43 to 4,57 m paving width. The screed is electrically heated, eliminating the need to change propane bottles in the middle of a large project. Dual vibrators provide 2500 VPM. The generous 9 t hopper capacity on the BF6615 allows high-production paving to continue between trucks. Even with its power saving system, the new paver can push asphalt feeder trucks while maintaining working speeds up to 55 m/min. The BF6615 also features a crawler style track drive system undercarriage with standard bolt-on polyurethane track pads. The weight of the machine is carried by 8 sealed rollers per side, while bolt-on rock guards installed on the inside and outside of each track drive prevent asphalt from loading up on the chains. Each of the track drives is bolted to a cross member frame structure and can be removed individually for maintenance. The entire undercarriage structure can be removed as well. The screed on the BF6615 features abrasion-resistant, extendable, reversible and independent hydraulic augers. Evenly distributing a uniform layer of asphalt across the mat, the 2 augers extend with the screed extensions, providing consistent material control at all paving widths and minimizing the need for hand labor. Screed extensions can be adjusted for a 5 cm crown or invert. Screed wear plates are 1 cm thickness abrasion-resistant 400 Brinell hardened steel. Designed to withstand harsh job-site conditions, screed plates are bolted on for easy replacement. The BF6615 features dual operating positions for control from either side of the paver. The engine is positioned low in the machine, giving the operator outstanding visibility from either side. Engine shroud is standard for heat and noise reduction. Fail-safe brakes are also standard. Both the augers and dual hydraulic slat conveyors offer full automatic control with manual override. This allows the operator to precisely control the amount of material being sent to the screed if paving wider or thicker on one side or the other.

|

|

© InfraStructures - Tous droits réservés - All rights reserved |