Autogreasers-101: Everything You Need to Know

About Automatic Lubrication Systems

Mike Deckert, Gabriel Lopez, FLO Components Ltd.

Special Collaboration

In a study conducted by a major component manufacturer, improper lubrication accounts for 53% of all bearing failures, a major cause of equipment downtime and significant maintenance costs. The majority of failures are caused by: contamination of bushings by dust, dirt and moisture; inadequate amounts of lubricant applied to bearings; or over-lubrication of key pivot points.

Direct costs resulting from inadequate lubrication include replacement bearings, labor to repair or replace bearings, unscheduled downtime and the impact on meeting customer delivery commitments. Indirect, but very real costs include work safety and housekeeping issues, wasted lube, environmental issues, and higher labor costs related to inefficient manual lubrication practices.

An Automatic Lubrication System (ALS) helps eliminate these unplanned and unnecessary expenses. Whether you know it as an automatic lubrication system, an autogreaser or a centralized grease lubrication system, an ALS automatically lubricates multiple points on a machine from a centralized pump/control unit which is mounted in an easily accessible location. A system dispenses small measured amounts of lubricant at frequent intervals, while your equipment is operating, maintaining a uniform supply of grease in the bearing at all times and a consistent lubricant seal to prevent dirt and contaminants from migrating into bearings. This is compared to the feast and famine conditions often associated with manual lubrication, where greasing is done “when there’s time”.

In talking with people who do not currently use ALS, we often hear statements like “Even if I use an Autogreaser, I still have to do a walk-around to inspect the system”. This is absolutely correct. An ALS will not replace your regular equipment maintenance inspection. You still have to check for loose or damaged lines and make sure that everything is operating smoothly. What an ALS does is take the grease gun out of your hand and replace it with a wrench. Then, you can use the grease lines as a guide and have the opportunity to focus on making any necessary adjustments or repairs as you conduct your regular inspection. In talking with people who do not currently use ALS, we often hear statements like “Even if I use an Autogreaser, I still have to do a walk-around to inspect the system”. This is absolutely correct. An ALS will not replace your regular equipment maintenance inspection. You still have to check for loose or damaged lines and make sure that everything is operating smoothly. What an ALS does is take the grease gun out of your hand and replace it with a wrench. Then, you can use the grease lines as a guide and have the opportunity to focus on making any necessary adjustments or repairs as you conduct your regular inspection.

So you might be asking yourself: “What’s the point of using an ALS?” There are 8 reasons why you would want to use an Automatic Lubrication System:

- Safety – An ALS helps to reduce or eliminate climbing over and under machinery or into difficult-to-reach areas. Whether you are an owner/operator of a single piece of equipment, or the fleet manager for a large operator, personnel safety in today's workplace is a key consideration.

- Efficient Lubrication – An ALS applies grease while the machine is running so you do not have to stop what you are doing or set aside time to lubricate it - in other words, less downtime. Furthermore, because the bearing is turning when it receives the grease, you get much better grease coverage on the bearing.

- Better Lubrication – Applying grease is often most effective when it is dispensed in small, measured amounts over short, frequent time intervals. Unfortunately, tight deadlines and manpower constraints or in some cases the location of the equipment often make this method of lubrication impossible. Equipment gets greased when it is available and when we have time and somebody available to do it. Clearly, this approach is not optimal for the point requiring lubrication. An ALS makes this problem go away.

- Better Housekeeping – How much grease is too much? If you are old-school, you keep pumping it in until you see it oozing out of the bearing. This is what we at FLO Components like to call “over lubrication”. As previously stated, frequent and small, measured amounts will give your bearings the best protection. In addition to no over/under lubrication, this also means that you get less spillage and leakage. The end results are less grease wastage and less mess on your equipment, site, parking lot, etc. Appearance aside, safety (danger of slipping) and environmental issues are even more important.

- Less Downtime, Reduced Maintenance Costs, & Reduced Bearing Replacement – Time and manpower constrains often make it nearly impossible to keep up with the greasing requirements of equipment, especially in the harsh Canadian climate. The “preventative maintenance” provided by an ALS is absolutely key to reducing maintenance costs and minimizing downtime by extending the life of the many pivots, bushings and components on the equipment. There are also fewer replacement parts to stock.

- Increased Overall Productivity – Resulting from an increase in machine availability and reduction in downtime due to breakdowns or general maintenance.

- Longer Equipment Life and Higher Resale Value – Because bearing areas are consistently protected and your machinery in general is better maintained.

- Helps the Environment – For the environment, less premature wear of bearings and other components means less landfill. Also, since you are not over greasing (see Better Housekeeping above), you are depleting fewer resources from the environment and you are not contaminating the environment with dripping grease.

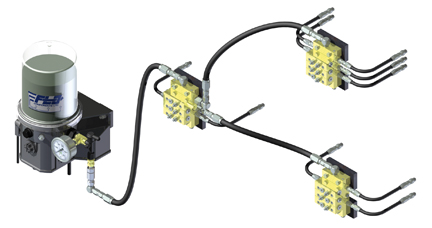

ALS systems vary in quality and design by manufacturer, but typically consist of 5 main components: a controller or timer to run the system; a pump and reservoir to store the grease; a supply line connecting the pump to the metering valves; metering valves or injectors to measure and distribute the lubricant and feed lines and fittings to deliver the lubricant to the application points.

There are several manufacturers offering automatic lubrication systems in the industry today, so when you're sourcing a system, it is important to make sure you're comparing apples to apples and asking the right questions. The first thing to know is that there are different operating principles by which ALS are designed. The two most common types of ALS used on mobile equipment are Series Progressive and Parallel.

In a single line progressive system, a pump delivers the lubricant to the lubrication points via progressive metering valves custom-sized for each application point. Lubricant flows through a primary valve which redirects to multiple secondary valves, and finally through feed lines to the ultimate application points. The nature of this system is such that if any line/bearing is not taking grease the entire system shuts down and there is (in a properly designed system) visual indication to the operator that there is a problem. This allows the operator an opportunity to take action before any damage occurs.

In a parallel type system, lubricant flows from the pump through a single supply line to multiple branches of injectors. The injectors operate simultaneously but are independent of each other. Each injector serves only one lubrication point and may be accurately adjusted to deliver the precise amount of grease or oil required. The nature of a parallel type system is such that only main line pressure is monitored, so if any feed line or bearing is not taking lubricant, the remainder of the system will continue to function normally, but the lubricant starved bearing may be lost. Note that in a properly designed system, there are indicator pins on each injector to allow an operator to visually confirm each individual feed line is operating.

Once you have decided on the type of system you want, other questions you would want to ask could include the following:

- Does the pump package include a high-pressure,inline, lubricant filter?

A filter prevents the introduction into the distribution lines of contaminants that can cause system failure and costly component replacement and labor costs. For most system manufacturers, a filter IS NOT supplied as standard - it must be specified.

- Are the hose and fittings standard NPT thread?

Some system manufacturers use metric hose ends and fittings. Special adapters are required to adapt to NPT bearing inlets causing increased costs and labor and possible delays during servicing if you are not prepared with the proper replacement fittings.

- Does the pump reservoir incorporate a revolving paddle or a follower plate?

A pump with transparent reservoir and revolving paddle eliminates grease cavitations (air bubbles in the grease that can cause system failure if they enter the system) and offers visual grease level monitoring. It also functions as a visual indicator to the operator that there is a problem if the paddle stops turning.

- Does the system include a pressure gauge?

A pressure gauge allows for visual monitoring of the system pressure during regular maintenance inspections. For most system manufacturers, a pressure gauge IS NOT supplied as standard - it must be specified.

- How are the steel lines mounted on the machine?

Some system manufacturers weld heavy wall steel lines (or tube) directly to the machine structure. The tube is connected directly to the bearing points. Replacement of damaged lines or bearings requires grinders, torches and welders to remove and replace the line. Other manufacturers have lines clamped and guarded with steel angle and C-channel. This allows for quick and easy trouble-shooting and replacement of any damaged line or guard in the field.

- Do the metering valves incorporate high-pressure, manual grease fittings?

Having a manual grease fitting at every metering valve allows for easier trouble-shooting, servicing, priming and flushing of grease lines. Not having a manual grease fitting means lines have to be disconnected to perform many of these tasks, substantially increasing labor costs. Most manufacturers either DO NOT include grease fittings, or use standard grease fittings which leak when faced with the high back pressure of a blocked line. Alternatively, using high-pressure grease fittings specifically designed to handle high back pressure, on every metering valve ensures that in the unlikely event of a blocked line, the only leak will occur where the machine operator will see it - at the pressure relief valve on the pump package.

- How do you know if a bearing is not getting grease?

With a progressive system, the metering valves work in series to each other. Some systems incorporate a cycle indicator pin (CIP) at the master valve assembly to provide visual confirmation of system cycling every time. If any line/bearing is not taking grease the entire system shuts down and there is visual indication (CIP) to the operator that there is a problem, allowing the operator an opportunity to take action before any damage occurs. In a parallel type system, the metering valves operate simultaneously but are independent. The parallel type system incorporates a pressure switch which only monitors main line pressure, so there is no indication (related to pressure) if each individual feed line is operating. The remainder of the system will continue to function normally, but the grease starved bearing will likely be lost. For some manufacturers' systems, if any feed line or bearing is not taking grease, the only visual indication is the lack of lubricant at the bearing point. Others will include indicator pins on every injector which move in and out as lubricant is dispensed to visually confirm each individual feed line is operating.

- Does the system require special grease?

Some systems used for on-road vehicles have a low maximum operating pressure, with small diameter hose/tubing and can only handle lube 000 through 0 (consistency of honey). In addition, if temperatures fall below -10°C, the #0 grease becomes too hard to pump and thinner grease must be used. Alternatively, in warmer climates, the thinner grease will drip away, causing potential damage to the bearings and environmental issues. Systems with higher maximum operating pressures will take any lubricant 000 through EP2 and can use any #2 chassis grease rated to perform down to -25°C. Also important to note, some manufacturers require you to purchase lubricant directly from them in order to warranty the system. Others have no restrictions on the brand of lubricant, which allows you to use your standard in-shop grease and considerably reduce inventory and costs.

In closing, an automatic lubrication system is a valuable tool in reducing the direct and indirect costs resulting from inadequate lubrication, but you need to understand how it works, the different types of systems available and which type best suits your (or your company’s) operation style. Most important of all, when sourcing an ALS, ask the questions outlined in this article and you will be on your way to purchasing a tool that will help maintain your equipment, reduce your costs and increase productivity for years to come.

_____

Mike Deckert, vice president of FLO Components Ltd., is an active member of the Conestoga College Advisory Council, Faculty and Board of Directors, an instructor of the Lubrication School at Mohawk College, an active member of the Canadian Lubrication Professionals and a Member in Good Standing of Society of Tribologists & Lubrication Engineers. Mr. Deckert is a graduate of Conestoga College of Applied Arts & Technology with an Industrial Maintenance (Millwright) Mechanic license. His wealth of knowledge and unique insight on the topic of lubrication was gained over three decades in such diverse roles as service technician, Off-Road Lubrication Specialist, sales manager, general manager and vice president in the industry. |